CAPABILITIES

Control Systems

Industrial automation control systems involve the integration of devices, machines, and equipment within the manufacturing plant. Industrial automation control system solutions require secure infrastructures to enable communications and data transfers as well as smart devices for the collection of data.

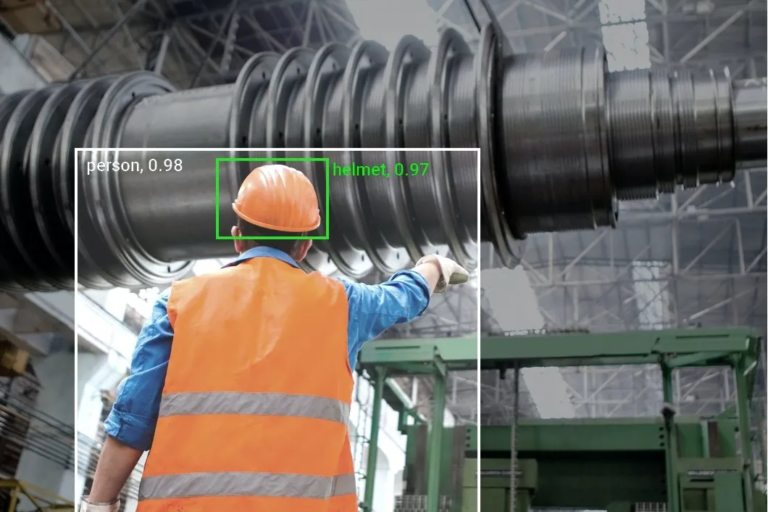

Quality Assurance And Safety

Industrial automation control systems involve the integration of devices, machines, and equipment within the manufacturing plant. Industrial automation control system solutions require secure infrastructures to enable communications and data transfers as well as smart devices for the collection of data.

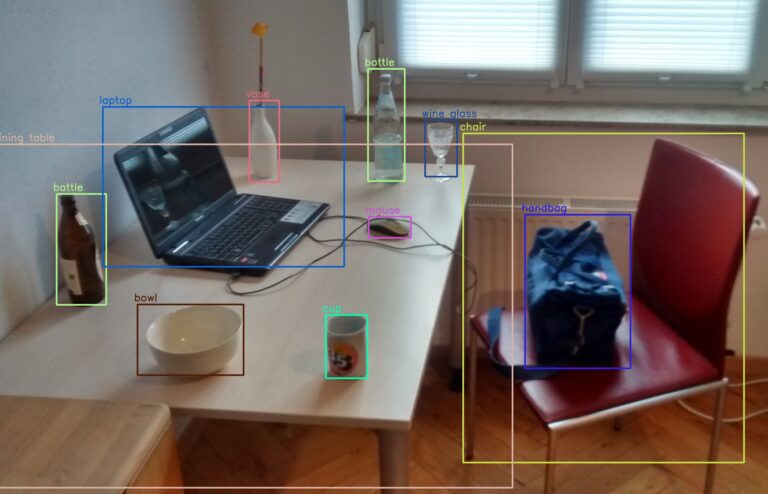

Machine Vision

Machine vision encompasses all industrial and non-industrial applications during which a mixture of hardware and software provide operational guidance to devices within the execution of their functions supported the capture and processing of images.

Robotic Automation

Robotic automation is a software technology that makes it easy to build, deploy, and manage software robots that emulate humans actions interacting with digital systems and software. Just like people, software robots can do things and perform a wide range of defined actions.

Material Handling

Material handling is an activity that involves movement of fabric or products within a corporation from one place to a different place or the flow of fabric or products to vehicles or from vehicles. The activities are usually confined within the boundaries of a corporation .

Industry 4.0

It’s important to realize an understanding of what’s meant by ‘industry 4.0’. Humans have collectively experienced three industrial revolutions since the 1800s; each revolution has been characterized by an exciting new technology that improved manufacturing and processes for the higher.

Automated Manufacturing

Automation, within the context of producing , is that the use of kit to automate systems or production processes. the top goal is to drive greater efficiency by either increasing production capacity or reducing costs, often both. Automation has become known more as using machines to scale back work performed by humans.

Auto Labeling

Auto labelling may be a game-changer however it required significant human intellect. Like most AI powered solutions, it requires creativity and iteration along the thanks to successfully generate time and resource savings. Using these features saves annotation time but you’ll still need to perform internal control checks on the work that’s done.

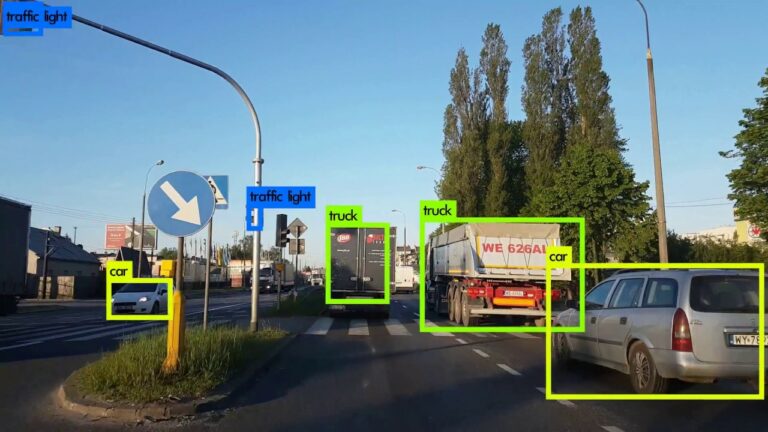

Object Detection

Object detection may be a computer vision technique for locating instances of objects in images or videos. Object detection algorithms typically leverage machine learning or deep learning to supply meaningful results. When humans check out images or video, we will recognize and locate objects of interest within a matter of moments.

Machine Tending

One of the most prevalent applications of collaborative robots on the market is machine tending. As long as the robot obtains raw parts, a robotic machine-tending operation may be repeated indefinitely. Robots are used in some sectors for a single phase of manufacturing, such as emptying injection machines or CNC machines.

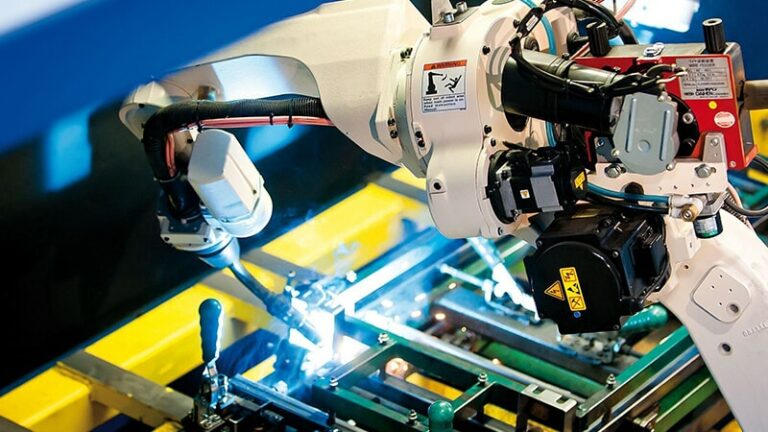

Robot Welding

Robot welding is that the use of mechanized programmable tools (robots), which completely automate a welding process by both performing the weld and handling the part. Processes like gas metal arc welding, while often automated, aren’t necessarily like robot welding, since a person’s operator sometimes prepares the materials to be welded.

Robotic Palletizing

Palletizing or palletization most often refers to the act of placing products on a pallet for shipment or storage in logistics supply chains. Ideally, products are stacked in a pattern that maximizes the amount of product in the load by weight and volume while being stable enough to prevent products from shifting, toppling, or crushing each other.

Waste Management Robotics and AI

When it comes to sorting, the role of Robotics and AI in recycling becomes incredibly intricate. That’s because AI-powered sensors are a vast improvement compared to traditional optic sensors. Segmentation in image processing allows to detect items made from different materials as well as nuances between items of the same material, including whether an item has been chemically contaminated, ensuring purity of the waste stream.

Automated Modular Construction

Automated Modular Construction is a process wherein sensors are widely used for automated monitoring of constructed structures as well as structures under construction. In structural health monitoring, constructed structures are measured to check for the presence of defects or reserve capacity.