INDUSTRY 4.0

What is industry 4.0?

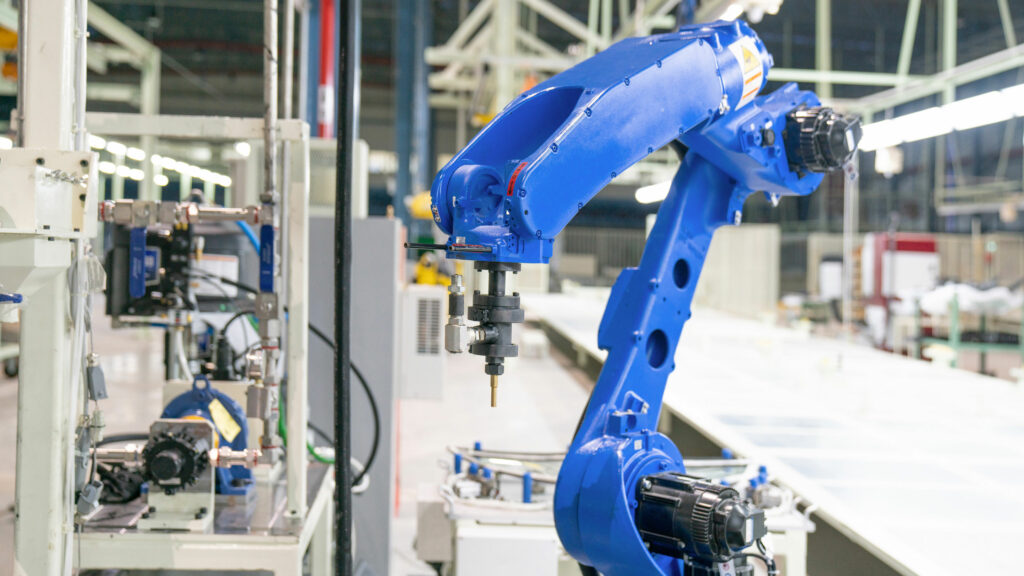

It’s important to realize an understanding of what’s meant by ‘industry 4.0’. Humans have collectively experienced three industrial revolutions since the 1800s; each revolution has been characterized by an exciting new technology that improved manufacturing and processes for the higher . The external-combustion engine , the production line , and therefore the computer have each been the catalyst for prior revolutions. Industry 4.0 refers to the present technological revolution that we discover ourselves in, led by the evolution of robotics, automation, and therefore the internet of things. Industry 4.0 heralds an age of ‘smart’ systems and digital integration; the name was coined in 2011, and therefore the associated movement is sending ripples through almost every industry round the globe

How Automation Helps ?

Improve productivity

Based on current projections, AI is predicted to possess the power to extend labour productivity by up to 40% by 2035.

Although some may even see robotics and AI as tools to exchange human workers, the International Federation of Robotics believes that but 10% of jobs might be fully automated; robots are generally designed to require on repetitive tasks and permit workers to specialise in more intensive duties.

lower overhead costs

Although the initial cost of automated software or robots could also be significant, the return on investment are often swift. Business owners might find that some roles are not any longer required once AI is being utilized, saving costs immediately. As an example, some restaurant industry leaders are utilizing delivery robots, which reduces their need for human workers. With fewer employees participating in hazardous work activities, businesses could also save on health and safety costs, with fewer injuries or day off work for his or her staff.

Reduce human error

Human error may be a factor that each business must plan for, and time and energy are both spent rectifying the problems once they occur. Particularly when it involves highly repetitive or mathematical tasks, automation could handle these with a far lower margin of error than human workers.

How Vancouver Automation can help you ?

Material Handling is an essential part of every automation system. Whether moving heavy awkward parts or small intricate precision components, efficient manipulation and control is essential. From the newest motor assembly to the most intricate surgical device, material handling and its flow ensures that components can be turned into assemblies that guarantees an assembly solution will not choke off critical up time or contribute to costly damage to parts or operators. Vancouver Automation through its experience along with its partners to provide technologically leading solutions that ensure the backbone of the custom equipment link together in support and harmony. There are many solutions that are tried and true and new flexible solutions that deal with the complexities in the market today. Material handling solutions range from linear solutions in layout and form too numerous to detail but include our partners: Robert Bosch power and free conveyor, belt driven solutions coupled with flexible feeders, bowls, hoppers with vision, and escapement devices that verify orientation and control throughout the assembly process.